Full Colour 3D Printing

The CARMEL 1400C – Ceramic AM System

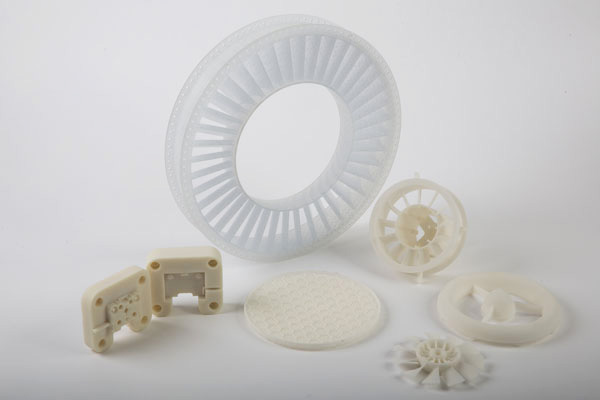

Our Carmel 1400C leverages XJet’s revolutionary NanoParticle Jetting™ (NPJ) technology. This patented inkjet technology enables the production of ceramic AM parts of the highest quality – featuring unprecedented levels of detailing, finish and accuracy – without compromising throughput or build time.

Industries We Serve

The medical industry has always been keen on adopting 3D printing technology. Additive manufacturing’s speed and versatility are ideal for a range of healthcare applications, from prosthetics to medical implants. Ceramic’s porous nature makes it even more useful for these processes. Traditional ways of making medical implants like artificial bones can be expensive and lengthy. Ceramics offer a porous surface similar to human bones, and 3D printing provides faster, cheaper manufacturing. Having both of these advantages can mean more patients can get affordable, life-changing operations.

These benefits are particularly helpful to the dental industry. People may not need artificial tibias that often, but false teeth are relatively common. Dentists could use 3D printed ceramics for artificial teeth as well as implants like crowns.

Some aerospace companies have also turned to ceramics 3D printing. Ceramic parts are durable and heat-resistant, two characteristics that come in handy in space travel. Unfortunately, spaceships and satellites often require intricate custom pieces, which can be tricky to make by traditional means.

To solve this problem, NASA worked with 3D printing companies to make ceramic parts for their spacecraft. Rockets tend to be expensive to manufacture, so aerospace companies need to save costs wherever they can. Using 3D printing to craft ceramic components instead of older methods is an effective way to do that.

Ceramics 3D printing also offers easier customization of parts. Since the process adds material instead of cutting it away, it’s not as challenging to make unique shapes — and to save on use of expensive materials. This quality is ideal for aerospace engineering, which often requires highly specialized components.

Handling electricity involves two crucial tasks: sending power somewhere and making sure it doesn’t go anywhere else. As a result, any electronics need both conductors and insulators. Ceramics offer excellent electricity insulation, making them ideal for electrical applications.

Like the aerospace industry, energy companies and electric devices often need small, unique parts. 3D printers are an obvious choice for this job, since they can make custom parts quickly and cheaply. 3D printing’s knack for customization, combined with ceramics’ insulative properties, is the perfect option for electronics applications.

3D printers can also work with a wide variety of different ceramic materials. This versatility allows companies to use custom ceramics that best serve their specific needs.

Cars have to go through a lot of stress and changing environments, so they need sturdy materials. To address this need, auto manufacturers use ceramics in everything from brakes to spark plugs to filters. Some automotive companies use microscopic layers of ceramics to protect your paint job.

With all these ceramic parts, car companies need a fast, affordable way to manufacture them. Enter ceramics 3D printing. 3D printing ceramics allows manufacturers to cut production costs, which means they can also sell their cars for less.

The same printer can produce all the different shapes needed for a car’s ceramic parts. Using 3D printed ceramics, automotive companies don’t need a variety of machines to make these components.