Metal 3D Printing

Device: DESKTOP METAL SHOP SYSTEM™

Desktop Metal aims to make metal 3D printing accessible to all Engineers, Designers and Manufacturers. We are reinventing the way engineering and manufacturing teams produce parts – from prototyping to mass production. We believe 3D printing will change the way parts are designed, manufactured and sold around the world.

Desktop Metal manufactures 3D printing solutions for all scales of production—from complex prototypes and on-demand tooling to the rapid manufacture of thousands of parts.

Materials

Developed by an in-house team of world-leading materials scientists and 3D printing innovators – as well as industry partners around the globe – Desktop Metal materials are designed to ensure print success and produce high-quality metal and composite parts.

17-4 PH Stainless Steel

The high alloy steel 17-4PH is one of the most commonly used precipitation hardened stainless steels. It contains about 17% chromium and 4% nickel with additions of copper. This type of steel has a martensitic crystalline structure in combination with a very hard and brittle structure that is due to stabilization via precipitation heat treatment. The corrosion resistance of 17-4PH is comparable to that of 304 stainless steel in most media. An excellent combination of high strength and good corrosion resistance at temperatures up to 316°C make this stainless steel extremely versatile and an effective solution for many applications.

Industries We Serve

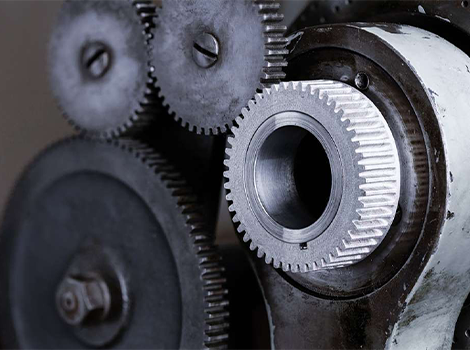

Additive manufacturing allows for rapid functional prototyping of complex automotive components and the creation of on-demand tooling – increasing design flexibility, shortening product development timelines, and streamlining production.

The technology also enables new business models and supply chains based on localized production, digital warehouses and the on-demand production of both custom components and spare parts.

Metal 3D printing benefits both product development and production. During development, it allows for quickly testing designs and collecting market feedback, and during production can create low-volume, regionally-targeted or mass-produced parts without tooling.

Printing also allows traditionally off-the-shelf components – like buttons, buckles, handles, lids and more – to be customized without the need for custom tooling.

From athletic equipment to faucets to fine jewellery, Desktop Metal customers are among the leading manufacturers of consumer goods across a wide range of industries.

Heavy industries – from industrial equipment manufacturing to chemical processing – require highly customized equipment and manufacturing facilities. Using 3D printing, complex parts can be created without custom tooling or post-processing – reducing per-part costs and enabling new, functionally-optimized designs.

The on-demand production and geometric freedom of 3D printing allows manufacturers to consolidate assemblies, easily produce one-off designs, and reduce costs for spare parts storage.

Educating future leaders in Advanced Manufacturing

We’re forming the next generation of additive manufacturing experts.

By investing in additive manufacturing, educational institutions can drive the exploration and adoption of groundbreaking technologies and help students develop the skills needed for next-generation manufacturing careers. Students will gain hands-on experience through the design and production of their own functional parts, researchers will develop new processes and materials that push the limits of additive manufacturing technology, and engineers will address pressing challenges by reimagining existing design processes.

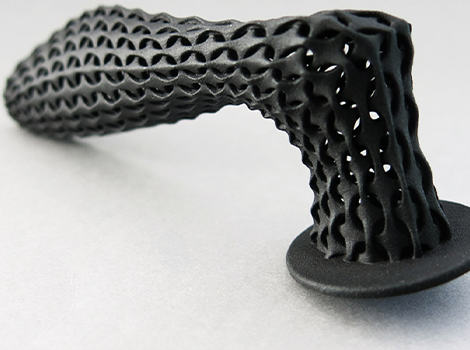

Using 3D printing, machine designers can print and test multiple variations of a part to quickly optimize designs. With greater design freedom, engineers can create parts that are unattainable with machining and consolidate large assemblies into fewer parts.

Without the need for tooling, manufacturers can customize and print new and replacement parts on demand, eliminating the need to warehouse thousands of different parts.